Quantum stress in nanofilms

Electrons confined in an aluminium film of a few atomic layers thick create mechanical stress equivalent to up to one thousand times the standard atmospheric pressures

Read heads in hard drives, lasers in DVD players, transistors on computer chips, and many other components all contain ultrathin films of metal or semiconductor materials. Stresses arise in thin films during their manufacture. These influence the optical and magnetic properties of the components, but also cause defects in crystal lattices, and in the end, lead to component failure. As researchers in the department of Eric Mittemeijer at the Max Planck Institute for Intelligent Systems in Stuttgart have now established, enormous stresses in the films are created by a quantum-mechanical mechanism that has been unknown until now, based on an effect by the name of quantum confinement. This effect can cause stresses equivalent to one thousand times standard atmospheric pressure, dependent of thickness. Knowledge of this could be helpful in controlling the optical and mechanical properties of thin-film systems and increase their mechanical stability. Additionally, very sensitive sensors might also be developed on the basis of this knowledge.

Films of metal, semiconductor materials or ceramics can be grown today one atomic layer at a time onto crystalline substrates such as silicon. Despite this atomic precision, defects invariably arise in crystal lattices of films only a few nanometres thick; sometimes only one atom is missing in a lattice where one should actually be. These kinds of lattice defects can impair the efficiency of solar cells or semiconductor lasers. One reason for this are stresses that arise in the film. Up to now, the main reason for these stresses was considered to be the growth of the film on a different material, so that the crystal lattice of the film did not coincide with that of the substrate. The atomic separations in the film were correspondingly contracted or expanded, with a compressive or tensile stress developing. Materials scientists working with Eric Mittemeijer, Director at the Max Planck Institute for Intelligent Systems in Stuttgart, have now discovered an additional mechanism that is able to create enormous stress in the ultrathin films.

David Flötotto and his colleagues discovered this mechanism as they analysed the stress in ultrathin aluminium films. They used an apparatus for this that precisely lays down one layer after another of aluminium atoms onto a silicon substrate, just the way a brick wall is built. By first measuring the stress in one single layer, then in a double-layer, a triple-layer and so on, the researchers found out how the stress in the aluminium film changed after deposition of each new layer. To do this, they determined how much the silicon substrate deformed due to this stress. And in doing so, they surprisingly established that the stress in the film fluctuated by about 100 megapascals as it thickened. By comparison, the standard pressure of the atmosphere at sea level amounts to about 0.1 megapascal.

The film expands and contracts, seeking the energy minimum

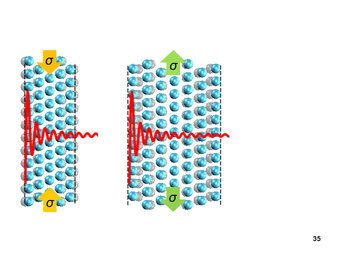

The foundation for this phenomenon lies in the electrons behaving differently in a thin film of a few atomic layers than in a thicker film. Due to quantum mechanics, the elementary particles are described not just as particles, but as waves as well. Since the thickness of films a few atomic layers thick is only somewhat larger than the wavelength of electrons, the electrons "sense" the boundaries of the film. This so-called quantum confinement sharply reduces the flexibility of electrons in absorbing and releasing energy. The electrons therefore only occupy discrete energy states.

The electron energy fluctuates with the continuously increasing film thickness. It first increases with thickness, then decreases, increases again, and so on. The principle that applies here is that everything possible will be done to minimize the energy of the system. The film seeks thicknesses for which the electron energy is as small as possible, i.e. the minima of this fluctuation. If the film grows one new atom layer thicker, it is either a bit too thick or too thin for this minimum. In the first case, it contracts, in the latter case it expands in order to attain the minimum energy.

The properties of ultrathin films can now be more suitably tailored

Expansion or contraction of the film thickness results in the atomic lattice parallel to the film wanting to expand or contract, respectively. Because it cannot do that due to its fixed connection to the substrate, a tensile or compressive stress develops in the film that the researchers have measured. When the film thickness has been augmented to five atomic layers, it contracts, and at seven atomic layers, it expands. To explain the stresses measured, the researchers in Stuttgart developed a model combining the theory of free electrons and Hooke's Law, as it is known, which describes the elastic behaviour of solid bodies.

The researchers see many potential applications for their discovery. “The better one understands how stresses develop in a thickening film, the better one can control its growth and avoid lattice defects,” says David Flötotto. Moreover, the mechanical strain in a thin film influences its electrical, optical and magnetic properties. “Properties such as these can now be tailored better for ultrathin films," Flötotto is convinced. The measurements of the stress can also be used to determine the thickness of a growing film very precisely. One could also exploit the effect not least for highly sensitive gas sensors. Because upon deposition of even the smallest amounts of gas onto the surface, the energy state of the electrons and thus the stresses in the film are altered.

The team is now working on making the effect viable for thick films as well (in the range of 100 nanometres). "We are working at the moment on freezing the state of the stress in order to control stress in a thicker film as well," says Flötotto. Properties like its mechanical stability can thus be improved.

CM/PH