Zika and yellow fever: Vaccines without eggs

Highly concentrated reproduction of some flaviviruses in bioreactors will become possible

This could make the supply of some vital vaccines more secure in the future. A team led by researchers from the Max Planck Institute for Dynamics of Complex Technical Systems in Magdeburg is developing methods with which viruses for vaccines can be replicated in significantly higher concentrations than before. The researchers produce the pathogens in cell cultures in small bioreactors. The production of vaccines currently requires about half a billion chicken eggs per annum, which causes some problems.

The production of vaccines often suffers from complications and bottlenecks. Because production must be planned years in advance, changes in vaccination recommendations, quality defects or even economic calculations by the few companies in the vaccine market have far-reaching consequences for the supply of the protective substances. In April 2017, for example, the US Center for Disease Control announced that the only licensed vaccine against yellow fever would no longer be available in the United States by the end of 2018. Although an alternative was offered which is not licensed in the USA, the limited availability of an effective vaccine could be dangerous in the event of an epidemic. For example, thousands of people became infected with the disease in 2016 during a yellow fever epidemic in Angola and the Congo. The World Health Organisation's stock of vaccine became so limited that the helpers had to vaccinate those at risk with only one fifth of the usual dose.

A combined approach for ideal virus production

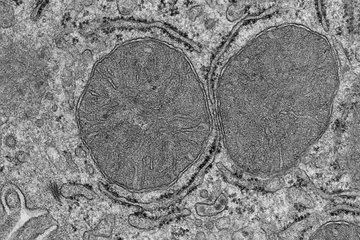

A team led by Yvonne Genzel and Alexander Nikolay from the Max Planck Institute for Dynamics of Complex Technical Systems is working on preventing such problems from occurring in the future. Researchers are combining several approaches for the production of flaviviruses under ideal conditions, including the pathogen that causes yellow fever. First they multiply animal cells in a bioreactor filled with nutrient solution, which serve as hosts for the viruses.

The cells multiply in suspension, i.e. floating in the nutrient solution. A device that regularly sucks in and pumps back part of the solution is connected to the bioreactor. A module containing dozens of membrane tubes permeable to the nutrient medium retains the cells but filters spent nutrient solution and waste out of the reactor. During this perfusion process, a probe continuously monitors the concentration of the cells, adjusting the supply of fresh culture medium. Researchers have achieved cell concentrations In the bioreactor up to 75 times higher than the usual standard.

The researchers then infect the cells with yellow fever viruses. In doing so, they use another trick to achieve the highest possible virus concentration. The scientists use a pathogen that they have previously adapted to multiply particularly well in animal cells.

Higher virus concentrations than any other known method

"Our progress is very promising," says Yvonne Genzel, who heads a team in the Bioprocess Technology working group at the Max Planck Institute in Magdeburg. "The new perfusion method makes it possible to produce viruses in extremely large quantities in a small space. This has enabled us to achieve higher virus concentrations for zika and yellow fever than any previous method has been able to deliver". Perfusion methods might be particularly suitable for the production of large quantities of viruses if the virus yield per cell is very low. "It would be good if this technology could soon be used on a large scale by vaccine manufacturers," explained Udo Reichl, Director of the Max Planck Institute for Dynamics of Complex Technical Systems and head of the Bioprocess Technology working group. "The method should make it possible to adapt production to demand more flexibly and finally find an efficient and economical production process for viruses that are difficult to multiply".

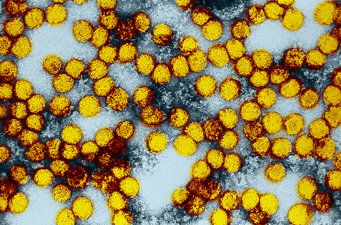

Flaviviruses are usually transmitted to humans via mosquitoes and trigger infectious diseases that can be fatal, such as yellow fever. At present an infection with flavivirus cannot be cured, medicines only relieve the symptoms. However, vaccination can protect against some of the pathogens.

A live vaccine against yellow fever has been available since 1937, but the manufacturing method has not changed fundamentally since the first production processes were established. Pharmaceutical companies are still multiplying the viruses in chicken embryos. They then produce live vaccines from viruses without disease-causing properties. They need eggs that are not contaminated by foreign substances and other pathogens and the production of a vaccine in this way takes about 12 months.

Viruses for ten million vaccine doses after two weeks

With the new production method, the number of yellow fever viruses that multiply in a bioreactor with one litre capacity in two weeks is equal to the number required for ten million vaccine doses. "Unfortunately, the viruses cannot be harvested directly through the hollow fibre membrane because the membrane becomes blocked over time," said Yvonne Genzel. "This is why we are also testing other perfusion systems without membranes".

Her team is also investigating how perfusion methods work with other pathogens such as the flu virus, the Japanese encephalitis virus and the modified vaccinia Ankara virus. The latter is a promising candidate to introduce genetic material into the cells of living organisms in gene therapy. Cancer treatment requires extremely high virus concentrations so that doctors can use this method to treat previously incurable tumours. If the perfusion method proves its worth in the planned research, viruses could become more readily available for many applications.

JT/PH