Fighting malaria with green chemical synthesis

A new production process could make the active ingredient artemisinin available to millions of malaria patients all over the world

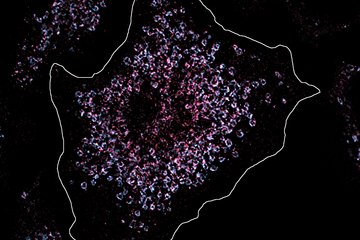

The most important active ingredient against malaria can now be produced in a considerably more efficient and environmentally friendly way. Researchers at the Max Planck Institute for Dynamics of Complex Technical Systems and the Max Planck Institute of Colloids and Interfaces in Potsdam have developed a new method, in which they use substances from plant waste to produce artemisinin. Artemisinin is an important component of the most effective anti-malaria drugs, and research is also being carried out on its potential use in the treatment of cancer. The new process, which can be industrialized on a massive scale, promises increased and low-cost production. For this reason, it is being industrialised by ArtemiFlow, a start-up established by Max Planck researchers, in Kentucky, USA.

At present, 650,000 people die of malaria annually, almost 600,000 of whom are children under the age of five, despite the fact that the disease responds well to treatment with medication. However, these effective anti-malaria drugs have been unaffordable for many people to date. This is now set to change: “Our breakthrough in the production of artemisinin has the potential to save millions of lives by reducing the cost of, and increasing global access to, anti-malaria drugs,” says Peter H. Seeberger, Director of the Biomolecular Systems Department at the Max Planck Institute of Colloids and Interfaces.

From plant components to artemisinin in just 15 minutes

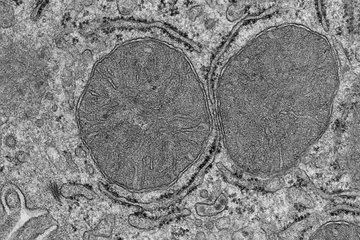

The chemist and his colleagues at the Max Planck Institute in Potsdam already attracted strong international attention in 2012 when they presented a simpler way of producing artemisinin. The active ingredient was previously isolated from the annual wormwood plant (Artemisia annua). At the time, the Max Planck researchers succeeded in producing the active ingredient from the biological precursor dihydroartemisinic acid, which was considered a waste product. Moreover, they did so using a continuous process that could be implemented on an industrialized scale.

A team headed by Kerry Gilmore, a scientist at the Max Planck Institute of Colloids and Interfaces, has now vastly improved the process. The plant raw material must no longer undergo a complicated cleaning process. In addition, the researchers use the plant’s own chlorophyll as a catalyst that powers the synthesis of the artemisinin: costly and environmentally harmful photoactivation agents were previously needed for this. The chemists can now feed a solution of the components that have been extracted from the plant directly into the continuous process. As a result, they can do something in less than 15 minutes that takes the plant around three weeks to do under natural conditions. The method is so efficient that it can process 50-100 times the natural concentrations of dihydroartemisinic acid.

New possibilities for drugs produced in a similar way

The new chemical production process is the first example of a method whereby the raw materials for the production of a drug or natural substance are not the only thing extracted from plants. The catalyst, namely the tool that powers the chemical reaction, also comes directly from the plants. “Our process is a low-cost, efficient, environmentally friendly, conceptual leap in natural product synthesis,” says Peter H. Seeberger. “It not only opens the door for other medicines to be produced in this way, but is the opportunity of a lifetime to transform the anti-malaria industry.”

The process to produce artemisinin is currently being implemented on an industrialized scale by the spin-off ArtemiFlow, which was founded by Peter H. Seeberger and Kerry Gilmore in the US state of Kentucky. “Because we now control the entire supply chain and are improving all of the phases involved in the large-scale production of malaria drugs, we are now in a position to industrialize the process,” said Kerry Gilmore. The team is also in negotiations with a series of potential partners, including the Bill & Melinda Gates Foundation, so that as many malaria patients as possible will soon be able to access treatment with effective drugs.