Jugglers in the chemistry lab

Catalysts crank up chemical reactions. Without them, the large-scale production of chemicals would be unthinkable. And whoever finds the best catalysts can manufacture more efficiently than anyone else. With astonishing creativity, the scientists headed by Ferdi Schüth, Director at the Max Planck Institute for Coal Research in Mülheim an der Ruhr, continue to develop effective new alternatives. The key to their success lies in cooperation between specialists in different disciplines.

Text: Tim Schröder

Basically, it all comes down to a little bit of powder – fine crystals in small glass tubes with plastic caps, or black dust in bulbous Erlenmeyer flasks. Hundreds of these containers are neatly arrayed on the laboratory shelves, each with a small adhesive label reading Cu/ZrO2, or Ca(AlH4)2. The sight of the laboratory is unspectacular, the tide of glass jars inconspicuously tidy. But looks can be deceptive. Without powder, there is no chemistry.

Ferdi Schüth is Director at the Max Planck Institute for Coal Research in Mülheim an der Ruhr and head of the Heterogeneous Catalysis working group. He is an acknowledged expert on the substances that make chemical reactions boil and bubble. “90 percent of chemistry is done by catalysts,” says Schüth. What he means is, hardly a single chemical process works without catalytic assistance. In some cases, it is these molecular pacemakers that activate the input materials in order to create the preconditions for a reaction. Frequently, they lower the reaction temperature, allowing the process to proceed under moderated conditions.

In other cases, they control the reaction so that fewer undesired byproducts are created. This can be decisive for the economic efficiency of chemical manufacturing. Schüth aims to develop new, effective catalysts as well as to optimize familiar substances and processes – in order, for example, to enhance the efficiency of methanol manufacturing, now that the latter is under discussion as a major source of hydrogen for fuel cells; or to simplify the synthesis of propylene oxide, an important ingredient in the production of plastics.

What is the origin of the term “heterogeneous catalysis”? It refers to the fact that catalysts exist in a different state than that of the substances which react to them. Generally, these molecular pacemakers are used in powder form, scattered into chemical solutions or exposed to a flow of gas. Their effectiveness is not solely dependent on the material composition: their structure and surface are also of importance. The larger the latter, the more room they provide for chemical reaction – allowing raw materials to be more efficiently converted. Even powders with particularly fine particles have a large surface area.

Schüth and his team therefore approach the development of their catalysts from several directions: in test tubes they culture filigree structures with vast surface areas. They create tiny, uniform hexagonal or octagonal particles a few nanometers (billionths of a meter) in size. And they remix established catalyst ingredients and test their efficiency in steel reaction vessels.

It always takes a touch of alchemy, says Schüth. Even though chemists nowadays are familiar with hundreds of catalytic substances, the mechanisms by which these work have often not yet been precisely decoded. “If you want to accelerate specific reactions, there is a whole range of known suspects,” Schüth explains. Take for example the nitrides or oxides of around 60 chemical elements. “On the other hand, for all the technical assistance at our disposal, producing the right catalysts with specific desired properties is still, to some extent, a matter of instinct.”

Microcapsules from the test tube

The working group at the Max Planck Institute is like a creative troupe that brilliantly juggles molecules. Their material is often familiar, but what they make of it is mostly quite new. Colleagues describe doctoral candidate Pablo Arnal as a true artist: it was he who manufactured miniscule microcapsules. “With a diameter of one micron, they are five times smaller than a red blood corpuscle,” Arnal proudly proclaims. These tiny catalytic spheres created by precipitation in the test tube are like transparent snowballs. The principle sounds almost trivial: stir some chemicals together in a liquid and they precipitate matter that gathers in the bottom of the test tube.

In fact, microcapsules are something of a rarity. But Arnal has succeeded in setting the parameters in such a way that, in a silicon solution, tiny silicon dioxide spheres are formed of exactly equal size. The researcher then encapsulates the tiny balls within a wafer-thin layer of zirconium oxide, which is the actual catalyst. Then the grand finale: Pablo Arnal dissolves the silicon spheres, leaving behind minute hollow bodies of zirconium oxide.

It may sound simple, but it took months of fine adjustment to get the parameters right. The pressure, pH value and temperature must all be correct, and even the size of the vessel affects the creation of these microspheres. Which chemical reactions the catalytic balls might someday accelerate is not yet clear. “Applications of that kind are not something we are primarily interested in,” emphasizes Ferdi Schüth. “Our initial task is a matter of basic research, developing methods that will advance science – but that might also ultimately open up new applications.” Much of the work done by the team in Mülheim is aimed at one objective – to increase the size of the catalytic surface. The scientists, meanwhile, have a substance at their disposal, one single gram of which has an area of 2,000 square meters. One of their many promising research projects involves a silicon skeleton discovered more or less by accident 13 years ago by employees of the oil conglomerate MobilOil. What the petrochemists were trying to create was a microscopic layer system that contained surfactants (in other words, soaps).

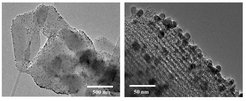

Under the electron microscope, however, it became clear that the silicon in the solution had arranged the surfactant molecules into regular hexagonal structures. Each time, they found a stack of cannelloni-like silicon tubes a few nanometers in thickness. It was only after a while that experts recognized the potential of the stack of tiny tubes. They are superbly suited to accommodating molecules – like the meat filling in cannelloni.

For creators of catalysts, these structures, known as “MCM-41” and “SBA-15,” are simply a matrix with a gigantic surface area. If the tubes can be stuffed with catalytic particles, the result will be a huge playground for chemical reactions that takes up minimal space. Schüth’s colleague Anhui Lu has been finding out what the possibilities are. In a multi-stage process, he fills the tubes with carbon and then adds nanoparticles of cobalt that are likewise coated with carbon. Finally, the silicon is dispersed, leaving behind magnetic, highly porous carbon. The cavities in the carbon are vacant, offering plenty of room for reactions.

A magnet that works like magic

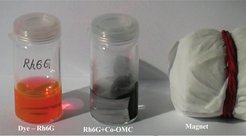

The resulting catalyst is well suited for use in liquids. The chemicals contained in the solution migrate into the tubes, where they react with one another. The particular feature is that, once the reaction has ended, the catalyst can simply be removed from the liquid with a magnet. The costly process of extraction by sieve or centrifuge becomes redundant.

Lu uses an experiment to demonstrate the action of his porous carbon with added cobalt: first he tips the catalyst into a glass containing a colored solution. Within seconds, the dye disappears – it migrates into the tubes, leaving the liquid clear. Lu then directs a magnet at the glass, and in a flash, the catalyst particles gather in a thick mass on the wall of the vessel. “If you have only cobalt particles in the solution, the magnetic attraction is so strong that it jerks the glass against the magnet,” says Lu. “In the beginning, we had quite a few glass shards.” That is why Lu now wraps the magnet in a soft cloth.

Sascha Vukojević, another doctoral candidate on Schüth’s team, and chemical engineer Manfred Schwickardi have also been studying surfaces under the Mülheim microscope. One of their specialties is activated carbon. This is a product of the combustion of material containing carbon, for example wood. Because it possesses exceptionally fine pores, it has long been used to filter air and water. Schwickardi, however, has been investigating its suitability as a matrix for the manufacture of tiny catalytic crumbs. And Vukojević has been testing various types of standard activated carbon by saturating them with copper nitrate and zinc nitrate solutions of varying concentrations. First, heat was applied to remove the liquid from the fine pores, just five nanometers or so in size. Then the researcher burned the activated carbon, leaving behind fine particles of catalyst.

“Copper and zinc compounds are classic catalytic substances. A lot of groups worldwide are working with these materials,” reports Vukojević. “But despite that, we are not one hundred percent sure how they function.” This is where the alchemy begins. The researchers must use trial and error to find the optimum catalyst. Vukojević, for example, compares his activated carbon catalysts with one another in minute detail. In this way, he is able to find out which copper or zirconium mixture is most efficient at assisting different reactions, and which activated carbon produces the most active catalysts. He then studies their structure under the electron microscope.

Vukojević is full of enthusiasm, for there are few better places to test and compare catalysts than in the laboratories of the Max Planck Institute for Coal Research. And not without reason: in recent years, Ferdi Schüth has made great strides in the development of so-called highthroughput systems. These are pieces of equipment in which the efficiency of large numbers of different catalysts can be tested simultaneously. One of the installations in Mülheim is investigating 529 catalysts in parallel to compare their ability to convert toxic oxides of nitrogen into harmless substances, such as nitrogen and oxygen.

The reactor behind the steel door

Some years ago, Schüth founded the “high throughput experimentation company” (hte) based in Heidelberg, which carries out high-throughput projects for other companies and also makes and markets high-throughput installations.

His white coat fluttering, Vukojević leads us from the large, brightly lit laboratory down a grubby corridor. The walls are hung with heating pipes and power cables. Neon tubes cast a cold light from the ceiling. The researcher hurries around corners and down steps until, finally, we enter a large room with heavy gray steel doors. The clamps that secure them are as long as a man’s arm. Vukojević pushes down on one of these and drags the massive door open. He points inside a narrow, windowless concrete chamber. On a table stands a gleaming, cooking pot-sized stainless steel container. Millimeter-thin metal hoses extend from its base and run to a computer. “This is our 49’er,” Sascha Vukojević explains – a high-throughput reactor with 49 finger-thick reaction chambers.

He uses the reactor to test his copper oxide and zirconium oxide catalysts. They are intended to convert hydrogen, carbon monoxide and carbon dioxide into a maximum yield of methanol – one of the most important industrial chemicals. “There was a time when every catalyst was tested individually,” says the scientist. That takes two days. Primarily because the catalyst must first be activated.

Eight hours pass before the oxidized copper is converted into its pure and avid form – copper zero.

The high-throughput system accelerates the process. First the different catalysts are activated simultaneously in the 49 chambers. Then, via a central valve, the computer passes metered doses of gases into each chamber. In order to measure the activity of the catalysts, they can be individually controlled with a rotary outlet valve. The resultant products are removed and transferred to the gas chromatograph for chemical analysis. “It still takes us two days, but in that time we will have tested 49 catalysts. That’s a huge saving of time,” explains Vukojević.

To show their paces, these substances need temperatures up to 250 degrees Celsius and pressures of up to 50 bar – 25 times the pressure of a normal car tire. Should the steel pot boil over and explode, the concrete walls and steel doors will hold back the fragments.

Between "new" and "slightly crazy"

A few years ago, Ferdi Schüth entered unexplored territory with his high-throughput systems. As a chemist, he is always open to new and at first seemingly abstruse projects. He has, for example, developed a computer program with which to “virtually” test the suitability of thousands of new catalysts to support specific reactions. Initially, when this procedure was presented at conferences, it was frequently subject to criticism. Meanwhile, however, it has become clear that the program works. “We often try to follow a path that leads between the new and the slightly crazy,” says Schüth. “Experiments are frequently best when they turn up something surprising. If you already know in advance precisely what happens in the end, you needn’t bother with the test.” Schüth’s team includes not just chemists, but physicists as well. They see catalytic substances through different eyes.

Frank Marlow, for instance, is investigating the optical characteristics of the finely structured porous substances manufactured by the chemists next door. “We are researching the basic principles behind the production of photonic crystals, micro-switches and microlasers, components that may one day be used in optical computers.” Such computers will one day use photons instead of electrons to process and transfer data. For this purpose, components will be required that can trap, switch and accurately transfer light.

Marlow has discovered that mesoporous silicon dioxide, a catalytic substrate with pores around three nanometers in diameter, lends itself to the construction of an optical resonator. This is comprised of two layers, one of silicon dioxide, upon which rests a second of polymer. Into the polymer, Marlow has etched a carefully arranged structure of larger pores (macro-pores) following a pattern in which perforated and untreated areas alternate like zebra stripes. Light is cast back and forth between these stripes. The porous area acts like a kind of mirror, while the untreated area serves as a conductor. The underlying mesoporous (= pore widths of between 2 and 50 nanometers) silicon dioxide layer serves as a barrier, preventing the light from breaking out of the polymer layer.

Bursting spheres become fine threads

In this multi-layer system, Marlow makes use of the fact that pores of differing diameters have different powers of refraction. “Resonators very selectively filter out specific wavelengths, and they are therefore suitable for processing information in data lines,” says the Max Planck researcher. Marlow still has some way to go with his sandwich structure. But there is evidence that the catalytic structure from the chemistry lab really does have the potential to advance the development of optical components.

Like the rest of his colleagues, Marlow, too, regularly comes by chance across new substances that are suitable for his light experiments – as on the occasion when an attempt to create small hollow balls of a titanium compound went awry. The substance was intended to arrange itself into a pattern of small spheres. But contrary to expectations, the spheres strung themselves together into threads like burst bubbles of chewing gum. These then surprisingly arranged themselves into a regular honeycomb with interesting properties. Visible light of specific wavelengths is bent through extreme angles and reflected.

Experiences such as these confirm the readiness of Ferdi Schüth and his team to expect the unexpected. “I rarely get upset when an experiment apparently fails,” says Schüth, “because it is often failure itself that brings new knowledge. The expected result frequently does no more than confirm what was already known or suspected.”